The Korean People's Army, the ever-victorious elite ranks, has formulated afresh the concept of a powerful army and the law of victory with its unique ideological and moral superiority of remaining absolutely loyal to the leadership of the Workers' Party of Korea, unparalleled mass heroism, matchless bravery and indomitable fighting spirit, and boosted the absolute might of the revolutionary armed forces to the peak of honour. It is marking its founding anniversary with pride, adding a page of shining victories and miracles to the great army-building history.

The KPA is adding to the greatness of the Party and the state and ushering in a new era of prosperity and development in the vanguard of the revolution seething with struggle and transformation for the eternal prosperity of the country and the wellbeing of the people, true to the sacred letters embroidered on its glorious colours. Its legendary feats and dynamic advance constitute a source of great pride of the state and the people and a symbol of their strong dignity and inexhaustible strength.

He was accompanied by Pak Jong Chon, vice-chairman of the Central Military Commission of the WPK and secretary of the WPK Central Committee.

All the commanding officers were filled with an overwhelming emotion and joy as they came to greet the great brilliant commander visiting the Ministry of National Defence with his ardent desire to put his trust, infinitely precious for the existence and development of the revolutionary armed forces, in them again on the significant Army Founding Day.

There was a solemn ceremony of greeting the Supreme Commander.

The Ministry of National Defence presented him with a bouquet of fragrant flowers reflecting the boundless reverence of all the KPA service personnel for him.

He was courteously greeted by major commanding officers of the Ministry of National Defence and commanders of the KPA large combined units.

Chairman Kim Jong Il's birth anniversary celebrated by workers

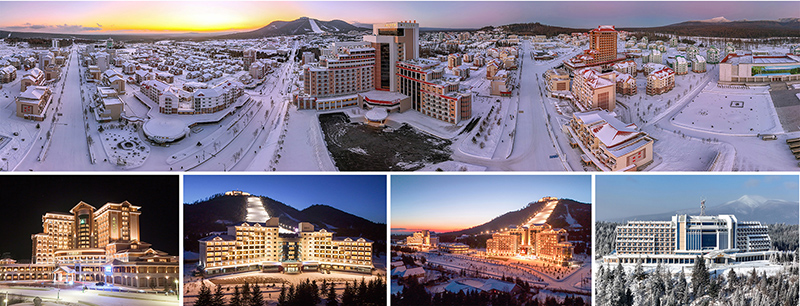

Chairman Kim Jong Il's birth anniversary celebrated by workers Great golden age of construction brings great transformation (2)

Great golden age of construction brings great transformation (2) Integrated school built in Rangnang District

Integrated school built in Rangnang District An eternal war trophy

An eternal war trophy Top 10 players of DPRK for 2025 (2)

Top 10 players of DPRK for 2025 (2) Gate shows distinctive architecture

Gate shows distinctive architecture Vietnamese diplomats pay floral tribute to great leaders

Vietnamese diplomats pay floral tribute to great leaders