The Workers' Party of Korea, the vanguard of the Korean revolution, is ushering in a new era of building a powerful nation by leading tens of millions of Korean people. Its sacred mission, strong pride and matchless fighting efficiency are bringing about a radical turn in the position and destiny of our country and people and placing the great strength, high dignity and eye-opening prosperity desired by all generations on this land on the majesty of history.

Our great Party has always performed and created miracles and glory of the DPRK by encouraging the people to the revolution in the long heroic course covered by the country. As it is standing as the ever-victorious banner and beacon of guidance, we have no dreams unrealizable and no difficulties insurmountable. This is not only the immutable truth engraved meaningfully again on the records of the times by 1 800-odd days of the past five years but also the steel-strong faith deeply cherished by all the people and service personnel of the People's Army in their hearts.

The eighth-term Central Committee of the WPK opened up a magnificent prelude to the overall national prosperity, fervently cheered by the people, through its bold pioneering and staunch struggle. It staked all its honour, dignity and destiny on that struggle in the period of extreme hardship that decided the destiny of the country and the people and influenced the rise and fall of the revolution. Its outstanding leadership activities provided a clear landmark and essential driving force for entering a new stage of struggle, further highlighting the validity of our cause and the inevitability of its victory.

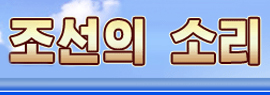

The Ninth Congress of the WPK, which marked a great watershed in the glorious course of strengthening the great Party and accomplishing the socialist cause, was held with splendor in Pyongyang, the capital city of the revolution, from February 19 to 25, 2026.

The Ninth Party Congress, held at a time when absolute trust in and single-minded loyalty to the WPK, the organizer and guide of our people for all victories, were soaring with the fervent desire for a new victory, left indelibly great traces in history.

It is the history of WPK congresses that it always reviewed its proud and honourable exploits for the country and the people, but there has been no such a congress as the Ninth Congress of the WPK that summed up the work of the period under review proudly with countless and valuable achievements to be specially recorded in history.

The Central Committee of the WPK, which brought to the hopeful eyes of the people the brilliant successes it achieved by racing against the clock, true to their desire and will, rather than the results produced by the lapse of time, has responsibly carried out its historic mission of bringing the turning phase in the course of socialist development to a higher stage, representing the destiny, future, faith and resourcefulness of millions of Party members and tens of millions of people.

The history of the Korean revolution is run through with the idea of building a nation, independent in politics, self-supporting in the economy and self-reliant in national defence, and the three revolutions—ideological, technological and cultural—the strategic line of socialist construction, by which it has overcome all trials and challenges. The nation-building idea and the banner of the three revolutions ensure not only today's priceless victory but also victorious development in the distant future one hundred and even one thousand years later. The Ninth Congress of the WPK solemnly demonstrated once again the immutable political spirit and will of the WPK to surely actualize all ideals and aspirations by regarding as its lifeline the nation-building idea and the banner of the three revolutions.

Through its Ninth Party Congress that indicated a new prospect of prosperity corresponding to the mature requirements of the Korean revolution and the strong patriotic enthusiasm and full confidence of the Korean people, the WPK further consolidated its undying prestige and leadership position as the powerful political staff for accomplishing the socialist cause.

Fireworks display in commemoration of Ninth Congress of WPK held

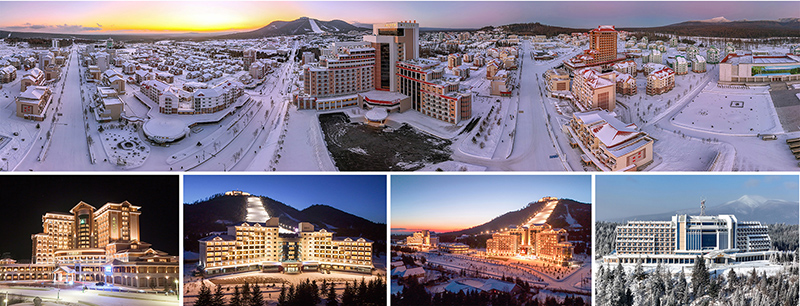

Fireworks display in commemoration of Ninth Congress of WPK held Great golden age of construction brings great transformation (2)

Great golden age of construction brings great transformation (2) People's art festival closes

People's art festival closes An eternal war trophy

An eternal war trophy Top 10 players of DPRK for 2025 (2)

Top 10 players of DPRK for 2025 (2) Gate shows distinctive architecture

Gate shows distinctive architecture Wreaths laid at Liberation Tower and cemetery of fallen fighters of Soviet Army

Wreaths laid at Liberation Tower and cemetery of fallen fighters of Soviet Army